Copper Brass Products

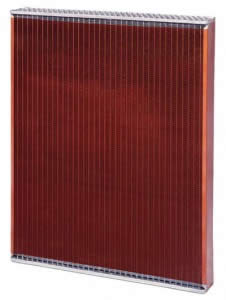

We offer a wide range of precisely engineered Complete Radiators & Cores that help in meeting various performance levels and allied requirements.

- All Type of On-Road, Off-Road Radiators & Industrial applications

- Copper – Brass Construction

- As per OEM & International Standards

- For Japanese, American, European & Korean Vehicle Applications

- Multi range of Tubes & Fin types

- Latest Technology machineries & high Quality Assurance as per industrial certification standards

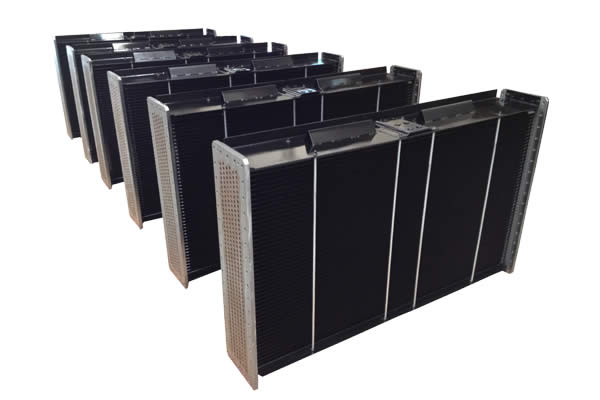

Caterpillar Modular Cooling systems uses an exclusive two pass cooling system & increased cooling surface area to provide significantly more cooling capacity than conventional systems, making work in higher ambient conditions.

Easy To service, modular panels are convenient and easily help to reduce your down time and costs.

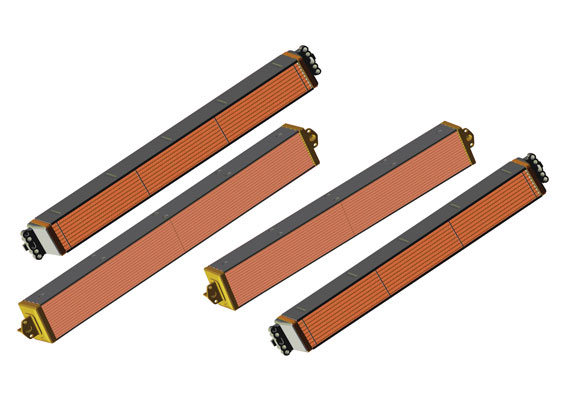

Copper Brass Locomotive radiators are made using special anneal-resistant alloys of copper and brass.

Features include

- Superior Quality, longer life cycle

- High performance, tolerance of elevated temperature

- Economic Efficiency, less power consumption

- Technological Leadership, advanced solutions conformable to all solutions

- Environmental Sustainability, reduced carbon footprint

- Corrosion Resistance

- Downtime Cost

- Durability

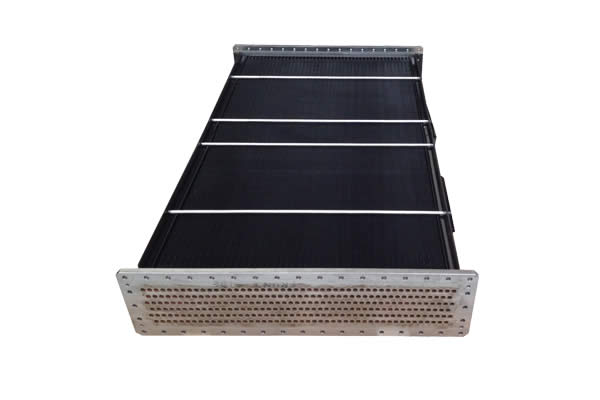

Horizontal Remote Radiators are suited to a wide variety of applications. Using a modular design method, ensures flexibility for different heat transfer surfaces such as water and oil.

Cooler performance is optimized by the use of ‘draw-through’ fans – This maximizes fan efficiency and air distribution across the heat transfer matrix.

The Horizontal Series offers extended service life, low noise levels, fan power levels, and the modular construction provides for easy maintenance and service activities.

The vertical series represents a range of cooling units able to incorporate heat transfer surfaces suitable for water, oil, compressed air and process fluids.

The ‘Axial Flow’ arrangement uses a duct mounted fan which provides scope to cater for additional air side resistance, as encountered in canopies, plant rooms and noise attenuated installations.

This product series is of heavy duty construction and provides inherent flexibility in installation, whether by direct mounting to the engine skid, wall-mounted, or alternatively, in a free standing situation. The modular construction allows ready access for ease of servicing.

Our vast range of radiators are used in various earth moving equipment’s. We provide copper and brass brazed radiators to suit diverse requirements of our clients. These radiators are coated from inside-out to make them sturdy and corrosion resistant. The rows and columns of tube in the radiator are provided as per the requirements. Its cooling capacity ranges between 6fpi and 10fpi according to different applications.

Dolphin manufactures a wide range of earth moving equipment’s radiators which include

- Caterpillar Models

- Komatsu Models

- JCB Models

- Detroit Models

- KATO Models

- Ford Models

Many radiators can have the core replaced, this is required when the core is leaking badly, too damaged to be repaired, fins are corroded, or the header plate is cracked or damaged. Re-coring uses your old tanks, brackets and transmission oil cooler. Re-coring is quite often a much cheaper option than a new radiator.

We have the technical expertise to repair most copper radiators. We can repair or replace brass tanks and replace plastic tanks. Aluminum or copper cores with plastic tanks are the majority of radiators supplied in modern motor vehicles. Today’s emission standards require higher engine temperatures which increase radiator contraction and expansion. These factors can lead to failures, causing costly engine or transmission damage. Cooling system’s should be regularly cleaned, many radiator blockages or are caused by contaminated or dirty coolants. Never mix coolants!!! Faulty radiators are often caused by mixed coolants.