Aluminium Brazed Products

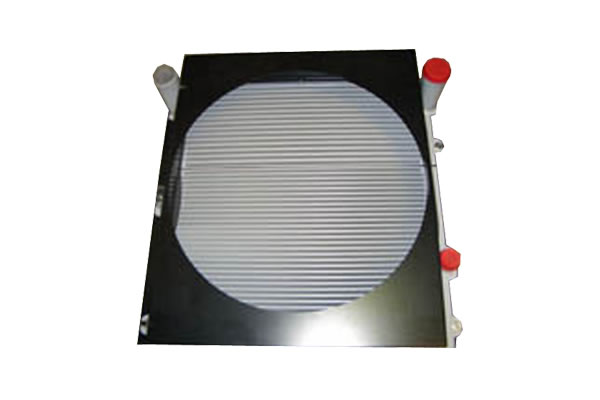

We offer a wide range of precisely engineered Complete Radiators & Cores that help in meeting various performances and allied requirements.

- Different Types of On Road, Off – Road & Industrial Radiators

- Complete Aluminum & Aluminum / Plastic Construction

- As per OEM & International Standards

- For Japanese, American, European & Korean vehicle Applications.

- Multi range of Tube & Fin types

- State-of-the-art machinery & high quality assurance as per recognized certification standards.

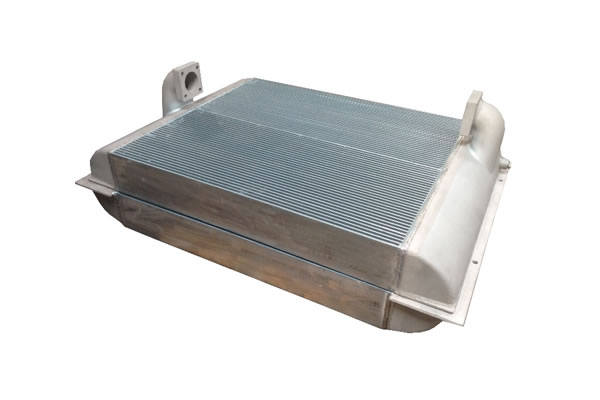

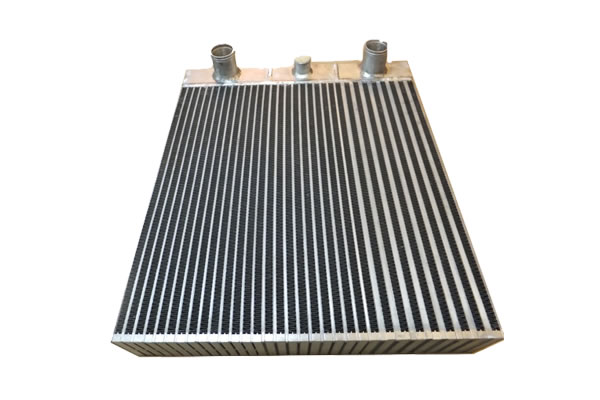

Dolphin provides a full range of aluminum Plate & Bar oil cooler’s. We design & manufacture After Cooler’s, Oil Cooler’s, Fuel Cooler’s, Charge-Air-Cooler’s, Radiator’s or a combination of cooling services (Combi Cooler’s, Air + Water + Oil) to meet your application requirements.

- All Type of Diesel Vehicles & stationary Diesel Engines

- Plate & Bar Oil Coolers for Trucks, Off Road & Industrial Applications

- As per OEM & International Standards

- High Pressure Applications

- Multi range of Tube & Fin Types

- High Thermal heat transfer Capacity & Cost Effective Products

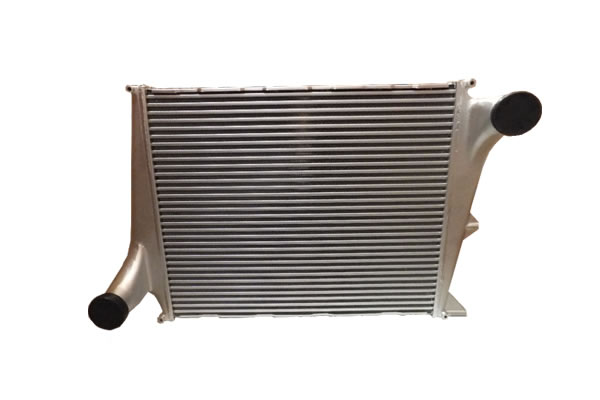

The aluminum charge air cooler (CAC) is becoming a popular and common in the O.E.M and aftermarket. Dolphin CAC cools supercharged air coming from the engine’s turbo while still meeting inlet air requirements. Available in multi pattern aluminum brazed construction style. Dolphin charge air coolers are manufactured as a vacuum brazed in all aluminum construction.

The charge air cooler core is assembled from component tubes, fins and internal fins. This assembly is then vacuum brazed together forming a single piece core. The resulting structure is tremendously strong due to the reinforcement provided by the external and internal fins. After the charge air cooler is assembled and brazed, the end tanks (or manifolds) are welded on to the core.

The welding process provides a means of attachment which is as strong as the aluminum itself. The fins are designed to trip the boundary layer of the air flow over them, thus reducing the thickness of the boundary layer and enhancing heat transfer.

Customized coolers are available for O.E.M and after market applications with the help of a in-house design facility.

- For all On-Road, Off-Road & Industrial Applications

- Maximum Core Size: 3 meters x 1.7 meters

- As per OEM & International Standards

- High Pressure Applications

- Multi range of Tube & Fin Types

- High Thermal heat transfer Capacity & Cost Effective Products